OnChip Introduces Capability to Design and Manufacture Custom Precision Thin Film Resistor Networks

OnChip Offers Quick-turn Custom Thin Film Resistor Arrays Ideal for High-Rel and Precision Applications

Santa Clara, CA – A global leader in Integrated Passives, OnChip Devices today announced the capability to design and manufacture custom Resistor Arrays with very short lead times. These Resistors can be specified by the customer and can include uncommon values, tight tolerances, and complex interconnections. These products can be available from concept to working samples in just a few weeks.

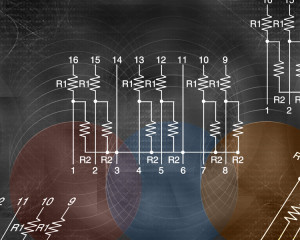

Design Engineers can mix and match resistor values to suit their exact application. The only specifications needed to get a custom network built by OnChip is to provide a schematic, resistor values, tolerances, and any special power or temperature coefficient requirements. These arrays can be built with tight ratio tolerances or matching between resistors. OnChip’s Thin Film Resistors feature greater electrical stability and higher precision while maintaining a miniature size. This is achieved by combining multiple Laser trimmable resistors on a single substrate, which requires less space than using discrete components. Resistors built on the same monolithic chip can have a wide range of different values and tolerances. With technology advancing rapidly, there is a pressing demand for systems to add more functionality and increase reliability while keeping the PC board compact. Thin Film Resistors cater to these critical needs. Furthermore, by incorporating custom resistor networks, the system adds an additional barrier to deter or prevent reverse engineering of the electronic hardware.

OnChip’s custom resistor networks have numerous applications ranging from medical to instrumentation to high-end audio and video equipment to commercial avionics. Using advanced thin-film manufacturing techniques and featuring high-stability, self-passivating and moisture-resistant Tantalum Nitride resistor elements, these products make ideal precision Voltage Dividers. Applications include gain control of operational amplifiers, setting the voltage for high voltage regulators, attenuations and a level shifter for interfacing TTL/MOS. These resistor arrays are tested to stringent military standards associated with high performance electronic components and feature resistance to thermal shock and high-temperature exposure. In Addition to Tantalum Nitride, OnChip has the capability to produce Nickel Chrome and Silicon Chrome films for very high resistor values. While Silicon is the most common substrate these films are sputter deposited on, OnChip also offers Alumina and Aluminum Nitride for Resistors that are used in high power application. These products are offered as bare-die or in standard Semiconductor IC Packages such as SOT, SOIC, QSOP, MSOP, TSSOP and DIP. All devices are 100% electrically tested and products shipped as bare-die are visually inspected to MIL-STD-883. All of these devices are operational in the full military temperature range of –55°C to +125°C.

Availability and Pricing

The custom thin film resistance network capability is available immediately at a Non-recurring engineering (NRE) charges ranging from $2,500 to $6,500 depending on the design complexity of the device. Products are shipped either in wafer-form, bare-die or as packaged products and can be built in 4 to 8 weeks. These components are designed and developed at OnChip Devices’ Santa Clara facility and are produced to the highest quality standards. Please contact sales@onchip.com for a quote or additional information.

About OnChip Devices

OnChip Devices is headquartered in Santa Clara, CA and is a global leader in Integrated Passive Devices. With its own wafer fabrication facility and strong partnerships with full turn-keys assembly and test houses in Asia, OnChip is offering state-of-the-art silicon and ceramic solutions for High-Brightness LED, Computing, and Consumer Electronics.