OnChip introduces a family of high reliability Thin Film Silicon Resistor Chips with die size of 12 x 12 mils sq for Medical, Aerospace, Military, Communication, and Instrumentation Applications

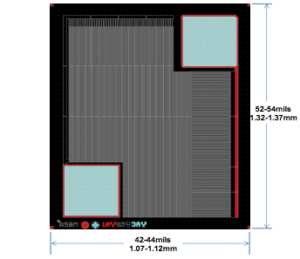

Santa Clara, CA – A global leader in Integrated Passives Devices (IPD), OnChip Devices today introduced a family of very small Thin Film Silicon wire-bondable Resistor Chips. These DR1212 resistor chips use sophisticated thin-film manufacturing process featuring a high-stability, self-passivating and moisture-resistant Tantalum Nitride resistor element. These chips offer 4 popular resistor values: 33, 100, 1K and 10K ohms. Additionally, these devices provide low shunt capacitance and low-noise operation which are ideal attributes for use in high performance hybrid microelectronics. The single value resistors have a very small die size of 12 x 12 mils sq and require two wire bonds. The Temperature Coefficient of Resistance (TCR) values as low as 25 ppm/°C.

The most common applications for these devices are termination and pull-up/pull-down. 100% electrically tested and visually inspected to MIL-STD-883, these silicon resistor chips feature resistance to thermal shock and high-temperature exposure. They are specified for an operating temperature range of –55°C to +125°C. Samples of all devices are available now, with lead times of 6 weeks for production quantities.

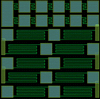

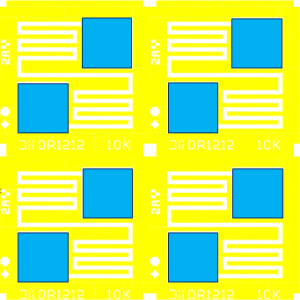

2×2 Array of 10K Ohm DR1212

Availability and Pricing

OnChip’s DR1212 resistor series is immediately available for purchase worldwide. These devices have production pricing in the range of $0.15 to $0.40, depending on volume and if the products are shipped on Mylar/Tape or in GelPaks/Waffle Packs. Samples are available immediately and standard lead time for production volume is 6 weeks upon receipt of order. Developed at the OnChip Santa Clara facility, these components are produced to the highest quality standards.

About OnChip Devices

OnChip Devices head-quartered in Santa Clara, CA is a global leader in Integrated Passive Devices. With its own silicon fabrication facility and strong partnerships with full turn-key assembly houses in Asia, OnChip is offering state-of-the-art silicon and ceramic solutions for High-brightness LED, Computing and Consumer Electronics.